The advantages and disadvantages of diaphragm pumps and peristaltic hose pumps.

Diaphragm pumps move fluids with suction developed by a shaking diaphragm, while peristaltic pipe pumps relocate liquids along by squeezing liquid-filled pipe with a one-way “milking” activity. Both sorts of pumps have distinctive benefits and disadvantages. Diaphragm pumps are normally a lot more intricate, and have more valves, so they often call for a lot more technical knowledge at first. Peristaltic pumps are easier, and function even more conveniently under tough problems, yet in time the tube calls for even more focus.

Advantages and Downsides of Diaphragm Pumps

Diaphragm pumps provide lots of advantages. With correct maintenance, they are cheaper to operate in the long term and they are a lot more energy-efficient since they apply even more pressure throughout the forward stroke of the pump. They are well-suited for pumping chemicals or various other potentially-damaging liquids, given that a well-kept diaphragm pump is less likely to leak. Ultimately, correctly-sized diaphragm pumps are better-suited to get over standing pressure in the flow line.

On the downside, diaphragm pumps function best when the fluid is tidy and devoid of fragments or gases. These pumps have check shutoffs, usually rounds found on both the consumption and discharge sides; if these shutoffs come to be blocked the pump will certainly end up being inaccurate in its metering ability and will certainly after that shed suction/prime. Furthermore, diaphragm pumps work best without back-pressure; in order to prime a diaphragm pump, it must be set to maximum stroke to get rid of any type of back-pressure. To settle these problems, diaphragm pumps usually have bleed valves to get rid of trapped air and sludge, and a feed-rate device to readjust inflow. Don’t get perplexed with air ran diaphragm pumps which do not have hemorrhage valves.

Benefits and Disadvantages of Peristaltic Hose Pumps

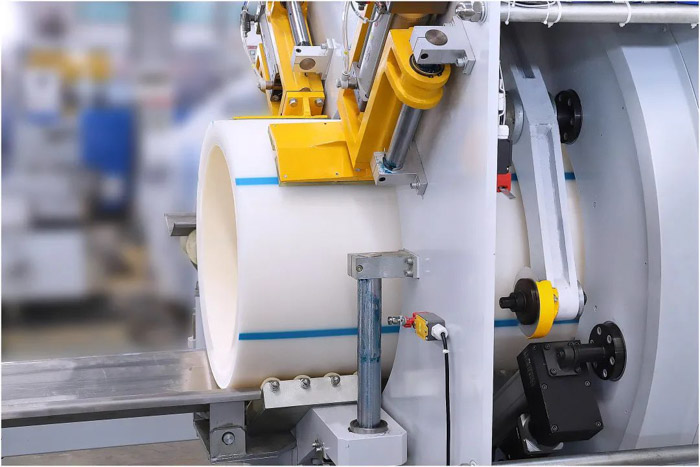

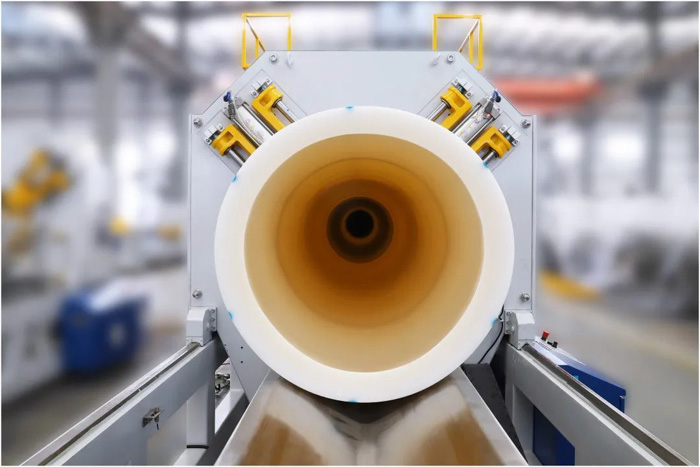

Peristaltic pumps are straightforward and easy to use and, they can handle thick or filthy fluids well, since there are no check valves to end up being blocked. Likewise, they run even more conveniently versus greater back-pressures and thicker services. Lastly, they prime conveniently and provide great suction capacities for a lot of liquids.

Still, peristaltic pumps have downsides, primarily involving their hose. By relentless squeezing, the hose is gradually damaged up until it deteriorates or additionally known as tiredness. Not just are the feed rate and pumping ability lessened with time, the pump motor itself is regularly under a load. Certainly, this work takes in much more power. Yet, the most severe disadvantage of peristaltic pumps entails the possibility that the pipe might burst. If undetected, caustic or hazardous liquids might leak and harm equipment or the pump covering. Although suppliers price these hoses and various other liquid-contact surfaces for a specific number of hours, individuals have a tendency to overstate the beneficial life of the hoses, which boosts the risk of inefficiency and leakages.

Summary

Diaphragm pumps usually function finest for tidy fluids and harsh chemicals in low-pressure applications, whereas peristaltic hose pumps execute far better with thick or dirty liquids including particle product, bubbles or entraped gases, specifically in high-pressure applications, yet the pipe should be kept track of to prevent leakages.

Global Pumps stocks both the peristaltic hose pumps and the air ran diaphragm pumps. Contact us today. We have more than 40-years’ experience collaborating with a vast array of industries and can suggest the best technique for you when it concerns setting up, keeping, or refurbishing your pumps.