Stainless steel staples can be a great alternative to nails in certain applications.

Here are some benefits of using stainless steel staples:

Corrosion resistance: Stainless steel is highly resistant to corrosion, making it an ideal material for use in outdoor or marine environments where exposure to moisture or saltwater can cause other materials to rust or deteriorate.

Strength: Stainless steel staples are strong and durable, making them a good choice for applications where a strong and secure connection is required.

Speed and efficiency: Staples can be driven quickly and easily with a staple gun, making them a fast and efficient way to attach materials.

Versatility: Staples can be used for a wide range of applications, including attaching wood, fabric, insulation, and more.

Reduced splitting: Unlike nails, which can split wood if not driven in properly, staples are less likely to cause splitting, making them a good choice for delicate or fragile materials.

Easy removal: Staples can be easily removed with a staple remover tool, making them a good choice for temporary or reversible applications.

When using stainless steel staples, it’s important to choose the right size and type for your specific application. 21 gauge staples Be sure to follow manufacturer recommendations and ensure that your staple gun is compatible with the size and type of staples you plan to use. Additionally, it’s important to wear appropriate safety gear, such as eye protection, when using a staple gun to avoid injury.

What are some common sizes and types of stainless steel staples?

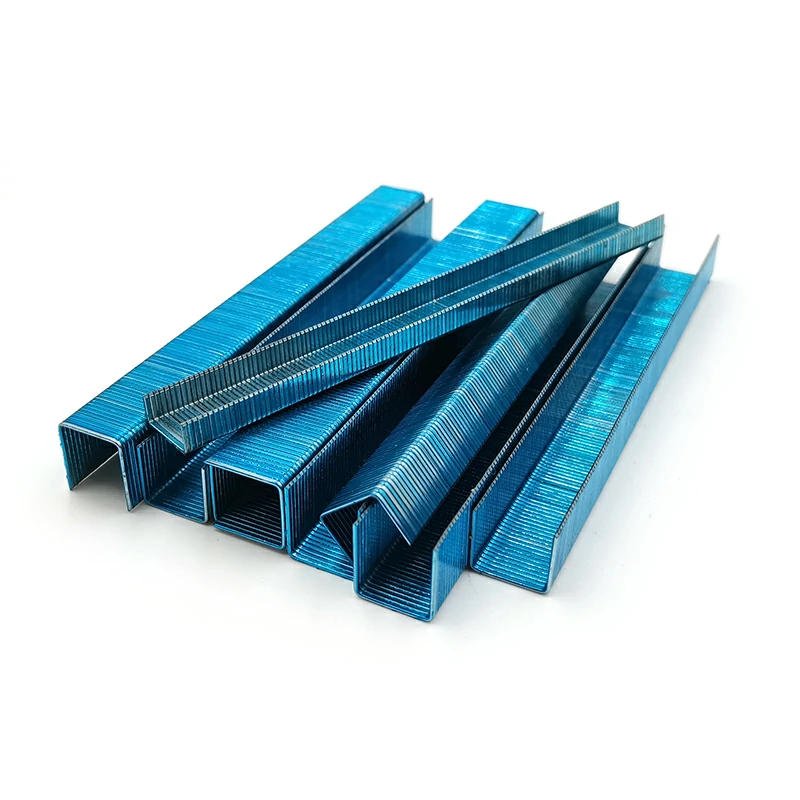

Stainless steel staples come in a range of sizes and types, each designed for specific applications.

Here are some common sizes and types of stainless steel staples:

Crown size: The crown size refers to the width of the staple. Some common crown sizes for stainless steel staples include 3/8 inch, 1/2 inch, and 5/8 inch.

Leg length: The leg length refers to the length of the staple legs. Common leg lengths for stainless steel staples range from 1/4 inch to 2 inches or more.

Wire gauge: The wire gauge refers to the thickness of the staple wire. Common wire gauges for stainless steel staples range from 18 gauge to 22 gauge.

Type: There are several types of stainless steel staples, including flat staples, chisel-point staples, divergent-point staples, and more. Each type is designed for specific applications and can affect the holding power and ease of installation of the staple.

When selecting stainless steel staples for your project, it’s important to choose the right size and type for the specific materials and application you will be working with. Be sure to read the manufacturer’s specifications and recommendations to ensure that you are using the correct staples for your needs.